Wood-based material replaces polystyrene.

- Henk De Vlaeminck

- 3 feb 2016

- Tempo di lettura: 2 min

Polystyrene is one of the most widely used plastics, the scale of its production being several billion kilograms per year. Polystyrene foam is a petroleum-based material, non-biodegradable and a major component of plastic debris in the ocean. The hope is to replace it with a renewable and biodegradable wood-based material. Cellufoam™ used as a new shock-absorbing material in a bicycle helmet, meets up to these expectations.

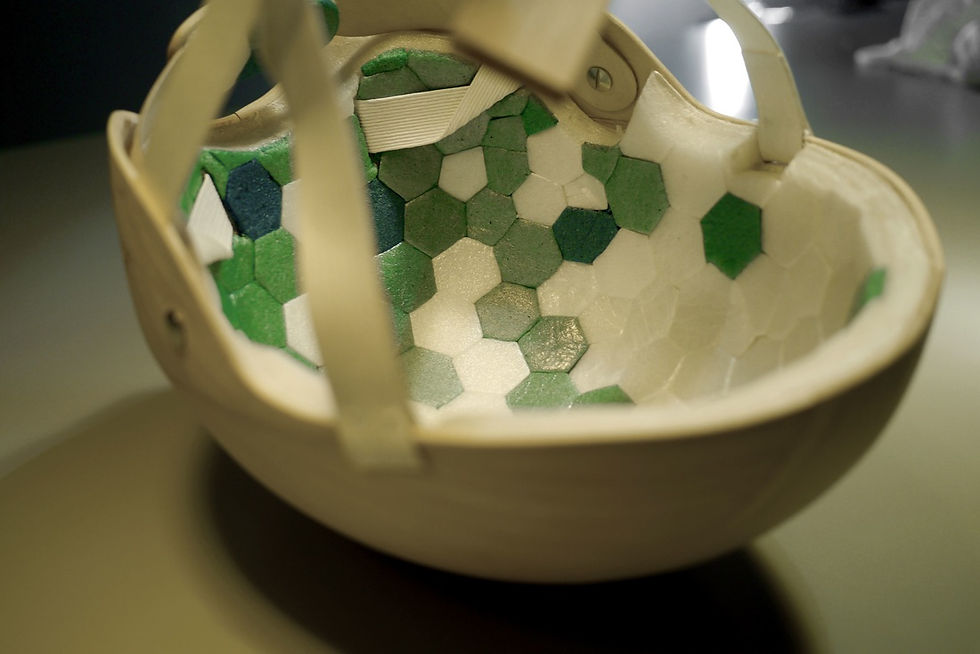

Bicycle helmet from the forest - Rasmus Malbert - Photo Cellutech

Designer Rasmus Malbert from Cellutech developed a bicycle helmet prototype entirely based on materials from the forest. Cellulose materials with different expressions were used in the design process. The helmet has an outer shell of wood veneer and straps made of durable paper. The cushioning inside, normally made out of polystyrene foam is replaced by Cellutech’s cellulose foam, Cellufoam™. The helmet concept is intended to draw attention to the possibilities of using wood cellulose as a sustainable alternative to Styrofoam and other foams from synthetic polymers.

“I think there is an incredibly strong potential in this material, we are just at the beginning of an exciting trend where more and more petroleum-based materials are replaced with renewable alternatives,” says designer Rasmus Malbert.

Cellufoam™ is a new and unique material made of nanocellulose produced from wood pulp and is therefore both renewable and biodegradable. The production begins with wood cellulose nanofibres, or fibrils, which are modified and mixed with a foaming agent water and air. Through the process of Pickering stabilization, these particles stabilize the air-bubbles in a way that is much better than by using simple surfactants.

“The properties of Cellufoam™ are suitable for use in e.g. lightweight construction, packaging materials and absorbent products.”

Researcher Lars Wågberg, a professor in Fibre Technology at Swedish KTH Royal Institute of Technology, says the wood-based foam material offers comparable properties to Styrofoam, but is from a renewable resource. By using different surface treatments and combinations with other material components, it could also be suitable for flame retardant materials, water filtration and antibacterial material.

Bicycle helmet cellufoam - Rasmus Malbert - Photo Cellutech

“The bicycle helmet is the first example of how Cellufoam™ can be used. Work is now in progress to find more suitable applications. There is currently an increasing need for renewable and biodegradable foam materials that can replace plastic foams.”

For futher information:

See this video.

Trademarked under the name Cellufoam, the material was developed by Wågberg together with Lennart Bergström, professor in Material Chemistry at Stockholm University KTH, and Nicholas Tchang Cervin, a former PhD student at KTH, in the Wallenberg Wood Science Center (WWSC). It has been further developed by Cellutech, a Stockholm startup that specializes in cutting edge materials made from wood, in conjunction with the Swedish Forest Industries Federation´s Ekoportal2035.

Comments